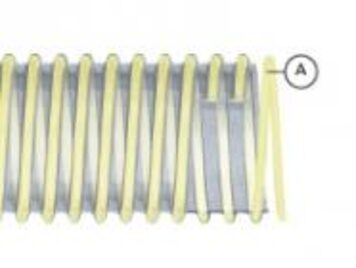

Ester-based TPU tube reinforced with steel spiral covered in copper-coloured TPU, to guarantee excellent adhesion to the wall and ensure maximum safety in use. Completely smooth internal surface to optimize the flow of transported vehicles; wall thickness 0.7 mm constant for all diameters. Robust but light and flexible, it is also suitable for heavy-duty work thanks to an abrasion resistance capacity of 20 mm3 (50% more than that of a normal TPU tube).

Resistant to mineral oils, aging, atmospheric agents, ozone and many chemicals, the tube is made of special TPU with combined characteristics that make the wall material permanently antistatic (R<10^9 Ohm/m) and resistant to UV rays . This compound also offers superior resistance to hydrolytic attack compared to normal foreign TPU tubes.

COLOR: translucent with high adhesion spiral in copper-plated steel covered in TPU

WORKING TEMPERATURE: -40 °C; +90°C.

FIELD OF APPLICATION: extraction systems, ceramic and wood industry, extraction of chips, sawdust, fumes and abrasive dust, even in critical conditions.

The tube can be made conductive (R<10^2 Ohm/m) by grounding the spiral.

Internal diameter(mm) |

Minimum thickness (mm) |

Weight(g/m) |

Depression (m H2O) |

Curvature radius(mm) |

50,8 |

0,7 |

365 |

2 |

50 |

60 |

0,7 |

480 |

1,7 |

70 |

63,5 |

0,7 |

515 |

1,7 |

70 |

65 |

0,7 |

525 |

1,7 |

75 |

70 |

0,7 |

565 |

1,7 |

85 |

76,2 |

0,7 |

615 |

1,7 |

90 |

80 |

0,7 |

615 |

1,6 |

95 |

90 |

0,7 |

690 |

1,6 |

105 |

100 |

0,7 |

830 |

1,3 |

135 |

102 |

0,7 |

845 |

1,3 |

135 |

110 |

0,7 |

875 |

1,2 |

145 |

120 |

0,7 |

960 |

1 |

160 |

127 |

0,7 |

1015 |

1 |

210 |

140 |

0,7 |

1045 |

0,8 |

185 |

152,4 |

0,7 |

1255 |

0,8 |

230 |

160 |

0,7 5 |

1325 |

0,7 |

250 |

180 |

0,7 |

1490 |

0,5 |

270 |

203,2 |

0,7 |

1850 |

0,4 |

300 |