Megalinear belts are made from polyurethane and offer excellent stability and resistance to heat and wear.

The insertion of steel cables, of various sections, gives excellent operating characteristics, even in the presence of high traction loads.

During production, a nylon cover can be added to the tooth and/or back of the belt, which reduces the friction coefficient. It is also possible, for specific applications, to create a customized product by inserting different types of cables (HP, Kev, HPF, etc.) inside the belt.

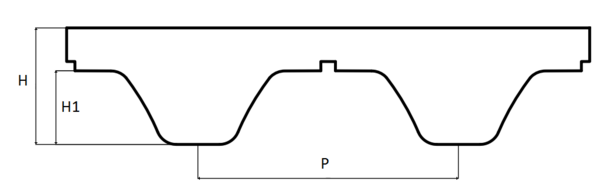

Section |

P (mm) |

H1 (mm) |

H (mm) |

T2,5 |

2,5 |

0,7 |

1,3 |

T5 |

5 |

1,2 |

2,2 |

T10 |

10 |

2,5 |

4,5 |

T20 |

20 |

5 |

8 |

AT3 |

3 |

1,1 |

1,9 |

AT5 |

5 |

1,2 |

2,7 |

AT10 |

10 |

2,5 |

4,5 |

AT20 |

20 |

5 |

8 |

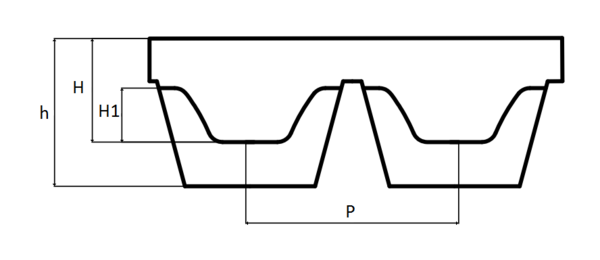

Section |

P (mm) |

H (mm) |

H1 (mm) |

h (mm) |

TG5 K6 |

5 |

2,2 |

1,2 |

4 |

TG10 K6 |

10 |

4,5 |

2,5 |

4 |

TG10 K13 |

10 |

4,5 |

2,5 |

6,5 |

TG20 K13 |

20 |

8,0 |

5,0 |

6,5 |

ATG10 K13 |

10 |

4,5 |

2,5 |

6,5 |

ATG20 K13 |

20 |

8,0 |

5,0 |

6,5 |

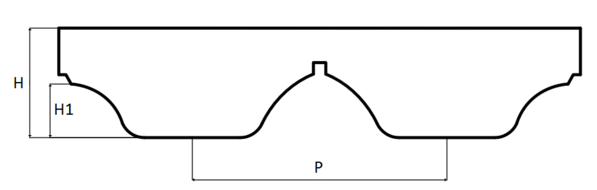

Section |

P (mm) |

H1 (mm) |

H (mm) |

MXL |

2,032 |

0,51 |

1,14 |

XL |

5,080 |

1,27 |

2,40 |

L |

9,525 |

1,91 |

3,60 |

H |

17,700 |

2,29 |

4,40 |

XH |

22,225 |

6,35 |

11,40 |