Megapower timing belts are produced with a special casting process. The high quality polyurethane gives excellent resistance to abrasion and cutting which, combined with a variety of steel cables of various sections, ensures high rigidity and tensile strength. The result is a drive belt with excellent dimensional stability. Megapower drive belts are manufactured with tight tolerances to ensure dimensional consistency. The combination of these factors results in a belt capable of providing excellent physical and chemical performance. Megapower polyurethane belts are recommended when high power transmission and movement precision are required, even at high speeds.

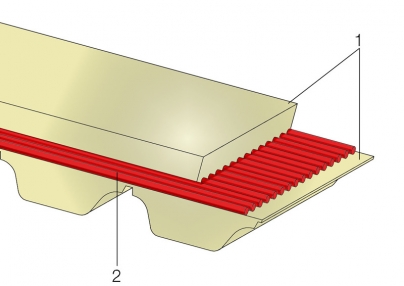

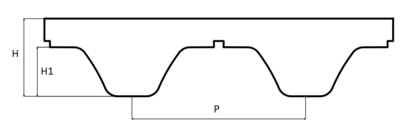

From the image of the belt you can see its two components:

1) The body of the belts is in grey/green thermosetting polyurethane, with hardness 88 ShA, characterized by high levels of wear resistance even in the presence of shocks and load peaks.

2) High resistance galvanized steel cables wound in a helical way which allow a high breaking load and low elongation.

Mechanical characteristics

- constant dimensional stability

- low pretension

- low noise

- high resistance to abrasion

- high flexibility

- linear speeds up to 80 m/sec

Chemical characteristics

- good resistance to ageing, hydrolysis, UVA rays, ozone

- operating temperatures from -30 °C to +80 °C (up to 110 °C for short periods)

- high resistance to oils and greases

- good resistance to many acids and alkalis

Megapower polyurethane belts are particularly suitable in the presence of pulsating loads and in the most varied applications such as textile machines, tools, woodworking, office automation, etc..

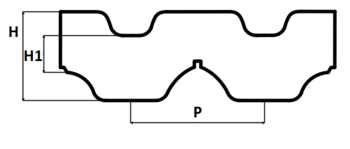

Model |

P (mm) |

H1 (mm) |

H (mm) |

T2,5 |

2,5 |

0,7 |

1,13 |

T5 |

5 |

1,2 |

2,2 |

T10 |

10 |

2,5 |

4,5 |

AT5 |

5 |

1,2 |

2,7 |

AT10 |

10 |

2,5 |

4,5 |

Model |

P (mm) |

H1 (mm) |

H (mm) |

MXL |

2,032 |

0,51 |

1,14 |

XL |

5,080 |

1,27 |

2,40 |

L |

9,525 |

1,91 |

3,60 |

H |

17,700 |

2,29 |

4,40 |

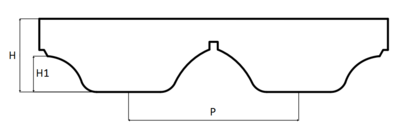

Model |

P (mm) |

H1 (mm) |

H (mm) |

T5 DD |

5 |

1,2 |

3,4 |

T10 DD |

10 |

2,5 |

7 |